An entrance door revolution!

Thermtek FL Aluminium Door

A little-known phenomenon has caused big problems for traditional thermal doors, except for the revolutionary Thermtek FL.

This phenomenon called the bimetallic effect, has caused nearly every thermally broken door in history to bow. This effect, caused by the superior thermal properties of the door, causes bowing and warping, making doors difficult or impossible to close and lock.

The problem with traditional thermally broken doors.

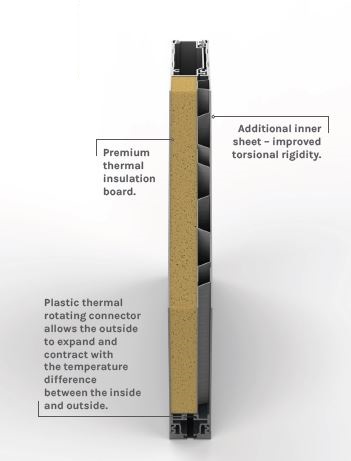

Experience shows the extreme temperatures on the face of a black door, if in direct sunlight, can cause the face of the door to heat up. Modern comforts, such as air conditioning, keep the inside of the house at a comfortable temperature, and consequentially, the inside skin of a thermally broken door stays cool.

The temperature differential, caused by these two different temperatures, causes the bimetallic effect – different rates of thermal expansion due to either a temperature or material difference. Simply put, the inside skin grows less from thermal expansion than the outside skin and the door bows.

Non-thermally broken doors don’t experience the same problems. Because these doors have no thermal break, the heat from the sun travels straight through the door, and the whole door grows at the same rate.

What we learnt.

After developing new doors since 1994, experience has taught us not to fight the elements. Changing nature is the only constant, so we must develop new doors that complement the environment, rather than conflict with more powerful forces.

The Thermtek FL has been designed to grow and shrink with the elements, with very minimal bowing. Testing this year, on Parkwood’s own test rig, showed maximum bowing of only 2mm with a temperature differential of 50 degrees. Traditional thermally broken doors generally struck above 6 millimetres under the same conditions.

Developing innovative methods of allowing this movement, while not compromising the structural integrity of the door were essential to the success of the project. After years of prototypes, the rotating rail connector and the sliding stile connector evolved. Both parts play a critical role in the mechanisms of the door. These parts allow a movement unique to the door, while still providing the solid and robust feel we can rely on.

Why such a focus on preventing bowing?

A door that bows too much can compromise security and sealing, two very important aspects that are depended on for an entrance door. Poor sealing can lead to the weather entering the home, and large amounts of heat loss. Bowing, also prevents effective locking, which can reduce the level of security in the home.

Heat loss.

The development didn’t just stop there! Further attention focused on reducing heat loss, resulted in a larger radius on the stile edges than previous doors. This not only provides a better door aesthetically, as well as better functionality, but dramatically reduces the thermal loss from the edges of the stiles.

Dual colour.

The new door has another added feature, a true dual colour, with the colour change on the stile of the door. Unlike the previous Thermtek CFL, the Thermtek FL has no capping on the face, allowing for a real dual colour option on all styles.

Supporting local.

What’s more, the new Thermtek FL has been designed, keeping local industry in mind. All parts are sourced from local producers in Australasia which helps us do our bit to keep local manufacturing alive!

Patented.

Because this door is so innovative, it was essential that we protected it with a patent. Patents have been filed in both New Zealand and Australia to protect the intellectual property associated with the door. For further information please see New Zealand Patent Application No. 778362, Australian Patent Application No. 2022204602.

Denbeigh Forrest