The new H1 door performance

Door thermal performance impacts a building’s energy efficiency. The revised energy efficiency standard in the NZ Building Code, H1, now treats door thermal performance the same as windows. This is a big change from previous versions of H1—where if the unglazed part of external doors was less than 6% or 6m2 of the total wall area (whichever was larger), there were no minimum R-value requirements at all. As a result, door performance lagged significantly behind windows. Doors made their own special contribution to New Zealand’s typically cold, damp, and hard to heat homes.

How bad was the impact on thermal performance under the previous H1 regime? Let’s take as an example, two homes built under the just superseded H1 requirements, a typical single-family detached home, and a townhouse. The door area is similar, nearly 6% of total wall area. A non-thermally broken aluminium door has an R-value of R0.12. Assuming 20% window area at R0.4, the doors in both homes lose a similar amount of heat as all the windows. (Doors and windows combined lose more heat than the remaining 74% of the R2 wall. This quite common situation illustrates the pressing need for specifying doors with better thermal performance.

Figure 1: Note that both of these doors cited in the example above contain glass. Their performance needs to be calculated per ISO10077-1/2 with the glass performance from EN673.

A common first step to fixing this performance deficit is switching to a thermally broken aluminium door. A timber, uPVC, or fiberglass insulated door or glazed door with low-e (low-emissivity) argon-filled double-glazing can also significantly increase the R-value.

Figure 2: Thermally broken aluminium entry door for increased thermal performance.

There are three methods available in the new H1 for showing that door thermal performance is compliant: schedule, calculation, and modeling. All require an understanding of the R-value specified for the schedule method because this is used for the sake of comparison if using the other method. Note that H1 Acceptable Solution 1 or 2 is commonly referred to as H1/AS1 or H1/AS2.

Schedule method

This is the easiest way to show compliance.

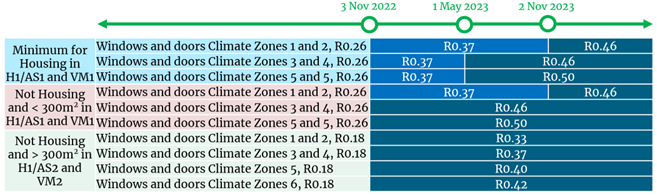

Table 1: The minimum R-value specified over time.

To show compliance with H1 via the schedule method, show that each part of the building complies: the roof, wall, floor and window/door R-values each exceeds the requirement). For both the H1/AS1 and AS2 Schedule method, either each door/window or the area weighted average of all the windows and doors must meet the R-value minimums set out in the table above.

| Door area that is glazed (including the frame around the glass and opening tolerances) is included in the definition of glazing area. This excludes opaque panels and opaque doors.

Opaque door area is the total area of opaque doors and opaque panels of doors in the thermal envelope, including frames and opening tolerances. |

H1/AS1 Schedule method requires that the opaque door area is no more than the larger of 6m2 or 6% of the total wall area. Glazed doors count as part of the window area for AS1. The AS2 schedule method allows for the sum of the window area and door area to be less than or equal to 50% of the total wall area.

Calculation method

If the doors do not meet the required R-value specified for the schedule method or are too large, the calculation method is the next easiest option. The H1/AS1 Calculation method can be used for much larger opaque door doors as there is no limit on the area provided the overall building exceeds the required performance. However, note that glazed doors count as windows regarding the limit on the window to overall wall area (40%).

H1/AS2 Calculation method allows a range of door performance and any door/window area below the limit. This method compares a reference building that has the schedule method R-values to the proposed building that has the actual values. Showing the proposed building performs better than the reference demonstrates compliance. I recommend looking at the NZGBC calculator here: https://nzgbc.h1calculator.org.nz/ for AS1 calculations.

Modeling Method and Alternative solutions

If compliance can’t be shown using either of the above two methods, then use the modeling methods H1/VM1 and VM2 to compare the overall building performance with a full computer simulation for a reference and proposed building. This approach provides a great deal of flexibility; designers can do pretty much what they like provided the overall building thermal performance of the proposed is better than a reference building and any hard requirements such as heated slab floor R-values are met.

| Opaque doors to roofs are not considered as skylights as they are a special case. For H1/AS1 and VM1 they can be treated as part of the roof and use the calculation or modeling method. For H1/AS2 opaque doors to roofs are technically not allowed, you would need to use the modeling method to H1/VM2. |

Finally, for very unique situations you can use the Alternative Solution approach to show the building consent authority that even though your solution is not allowed, even by the modeling method, your building is compliant. As the modeling method is so flexible, I don’t expect this to be needed in practice.

How to calculate a door R-value?

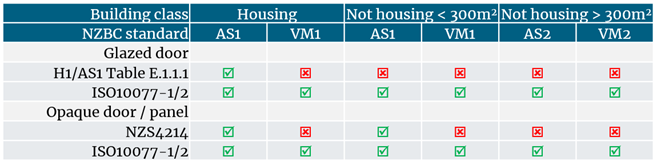

There are several permitted methods that can be used to calculate the door R-value. Which method is permitted depends on the method being used to show compliance. The intent is that the thermal performance of doors (both opaque and glazed and including the frame) would be calculated per ISO10077-1 and ISO10077-2. These calculations are complex and are intended to be done by manufacturers or consultants. I expect several manufacturers will use simpler methods, such as using the tables in H1/AS1 or simplified calculations. Refer to the table below to make sure you are using values that are suitable for showing compliance.

Table 2: How to calculate the door R-value. Note that using R-values calculated per ISO10077-1/2 is permitted in all cases.

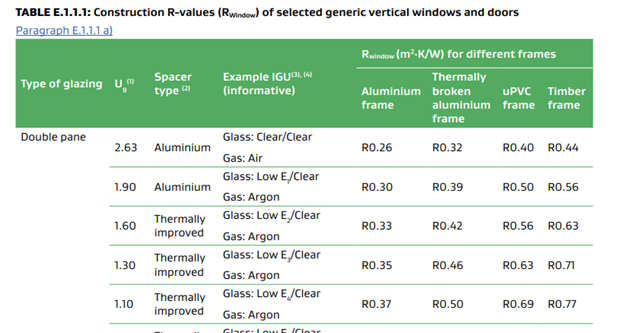

Using Table E1.1.1

As the table above shows, any size house can show compliance via Table E1.1.1 using AS1 (either schedule or calculation methods). It’s simple if the glass Ug value per EN673 is known. Simply select the next higher Ug value and read across to the appropriate frame type to find the minimum R-value for a glazed door.

For example (below): The data sheet value is Ug=1.8. Round up to the next highest Ug value in the table: here, Ug=1.9. The R-value for a thermally broken aluminium frame door is R0.39.

Table 3: Excerpt from H1/AS1 5th edition.

Using NZS4214

Table E.1.1.1 cannot be used for opaque doors. For housing of any size (and for buildings that aren’t housing that are less than 300m2) NZS4214 calculation methods can be used. This leads to a minimum of R0.12 for a non-thermally broken frame door, as the surface films are fixed at R0.03 on the exterior and R0.09 on the interior and the aluminium door panel and frame have negligible thermal resistance (ie less than R0.01). However, per H1/AS1 2.1.3.9 a value of R0.18 can be assumed for any unknown opaque construction value.

| Passive House and Homestar V5 use the same ISO10077-1/2 methodology for window and door performance calculations as the new NZBC but also consider the installation thermal bridge losses. This is the additional heat lost around the edge of the windows due to how they are installed into the building. This can be significant (See PHINZ High Performance Construction Details for examples) but are ignored for NZBC compliance for all methods: schedule, calculation and modeling. |

The intent of this Building Code update was to use the ISO10077 standards for opaque doors and panels. NZS 4214 for H1/AS1 housing was left in for the sake of smaller manufacturers.

Using ISO10077-1/2 methods

Door R-values calculated per ISO10077-1 and ISO10077-2 can be used to show compliance by any method, so this is a recommended approach. It requires getting into the fine details of how the doors are manufactured so it’s not something individual designers should contemplate doing. The calculations are complex and are intended to be done by manufacturers or their consultants. Sustainable Engineering has been engaged by several door and window manufacturers to provide these calculations.

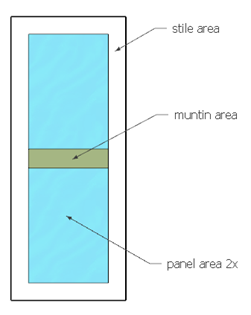

The methods in ISO10077-1 provide some default conservative values and detail how to add up the overall door performance for each calculated section. In the figure below for an opaque door the performance of each portion of the door (stiles, muntin and opaque panels) is added up and an overall door R-value calculated.

A glazed door would be slightly more complicated as the additional thermal losses at the edge of the glass panels need to be added in.

Figure 3: Example overall door performance from components for an opaque panel. For a glazed panel the glass-to-frame thermal bridge, PSI-g, also needs to be included.

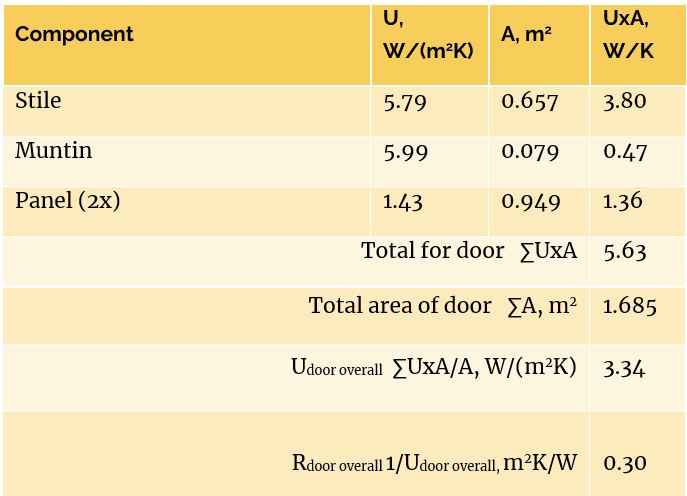

Calculation of the door R-values per ISO10077-1 is made much easier by use of a calculator which adds up these components. An example calculator is shown below. This allows the manufacturer to simply type in the door dimensions and select the components from drop down lists and output a detailed R-value calculation for each door in the order.

Figure 4: Joinery calculator in accordance with ISO10077-1. The specified frames and panels or glass are added up in a practical tool. The frame sizes are entered, and the components are selected via the drop-down.

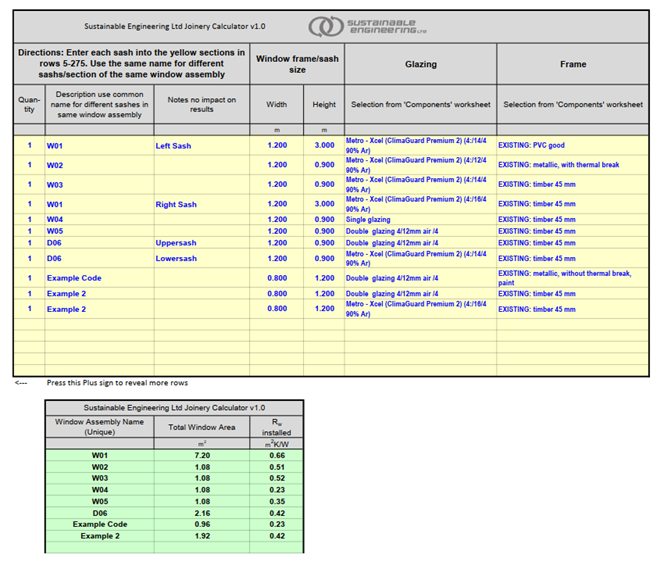

Hidden away in this calculator is the component thermal performance of the stile, muntin etc. In order to obtain the U-value for the stile or muntin, a detailed thermal calculation per ISO10077-2 for the specific profile and materials needs to be completed. In New Zealand this is typically done with THERM or Flixo software. A typical style thermal calculation using Flixo is shown below.

Figure 5: Frame Uf calculation using Flixo in accordance with ISO10077-2.

Jason E. Quinn CMEngNZ IntPE(USA)