PERSONNEL ACCESS EGRESS DOORS

A personnel door is normally a hinged door used for people, as opposed to vehicles or machinery, and is found on engine rooms, commercial buildings as fire exits, storage rooms and even in wet areas. It must be hard-wearing and of a commercial grade to resist the industrial wear and tear that a residential entry door is not exposed to.

What benefits do you want to receive from your personnel access door? What features should you look for in a brand of door and its supplier? What are the possible pitfalls to watch out for when selecting the manufacturer of an egress door for your project? This article will attempt to answer each of these questions to give you some focus and direction in selecting the egress door and frame unit for your commercial or industrial project.

The terms personnel access doors or egress doors are used throughout this article but they both refer to the same commercial industrial door category.

Free Revit and DWG file downloads for PA doors

What are personnel access doors used for?

Personnel access doors are used in a variety of places. The most common is the small man-door beside the large roller doors. These are often used to initially unlock the building, before the main roller doors are opened, and as fire exits. This means they need a simple locking system for easy and fast access when opening up the building in the morning. They need to be simple to operate in the case of a fire, so people can get out of the building quickly if the roller door is not open. Also, in the case of a fire, it is normally better to leave the roller door closed as this decreases air flow, meaning a small escape through an egress door is essential.

Egress doors are used on engine rooms. These may house the air conditioning, heating or air extraction systems for a large office building or factory. These plants are often critical to the running of the operations in the building, so keeping them safe and secure if paramount. Doors could also be used to allow greater ventilation to the machinery in their confined space through door grills and vents.

These industrial doors are also used in wet areas where a normal custom wood hollow-core door is not suitable. Wet areas could be public toilets, swimming pool changing sheds, milking sheds, or food processing areas where frequent washing down is required. The usual timber or custom wood door would absorb moisture, swell, and fall apart if it was subjected to a lot of wet treatment. Personnel access doors would be water resistant and suitable for frequent washing down.

What benefits do you hope to receive with an egress door?

The main benefits you would hope to receive from these commercial doors are security, strength, and insulation.

The more important benefit provided should be security. Industrial buildings normally store valuable goods or machinery and can often be left alone for long periods of time. For example, commercial subdivisions can be deserted over weekends. These goods need to be protected by a secure building with well thought out access protection.

Secondly, the complete unit (door, frame, and lock system) needs to be strong. The door needs to have decent bracing around the edges to withstand force, and its core needs to resist ramming or possible breakthroughs. The skin or surface of the egress door and the backing to the skin of the door need to withstand bumps and the fairly rigorous wear and tear of an industrial factory. Trolleys, small freight, and other small machines often use these doorways when the roller door is not open and will often bump and bounce against the door and frame as they go through. Due to the requirements of a door staying straight, they are not normally completely solid. The manufacturer needs to ensure there is sufficient backing to the outer surface, so they do not buckle under a bit of a knock.

The frame needs to have a decent structure so that it can withstand forced entry with crow bars and battering rams. It also needs to be able to handle the full door, often quite wide in commercial situations, constantly slamming and being blown around in the wind. The force of a large door doing this can wear a basic frame down over time.

Finally, a third major benefit required of an egress door is insulation. This is often needed on food cool stores, or to simply keep the heat out of large factory in summer, or warmth in during winter. A major factor in determining the insulation rating of a door is the material in its core. Some personnel access doors are hollow, and others are aluminium extrusions. The best insulating core is an expanding foam or polystyrene filled. These are the best insulators of the transfer of energy and will also help to reduce sound travel through the door. Another aspect in improving insulation is the glazing in an egress door. The glass is often within a ‘vision panel’. Glass is normally the main downfall in the insulation rating of a shell or wall. However, if you request laminated or double-glazed glass, this will bring the vision panel unit up to the rating of the door.

What features should you look for in a brand of door and its supplier?

There are a range of features available with your personal access doors. Good manufacturers should be able to provide these add-ons and customisations.

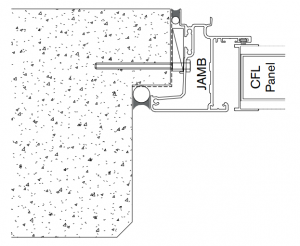

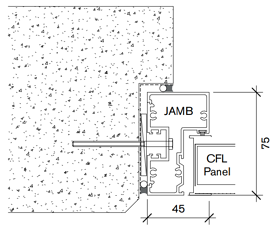

Firstly, a major aspect in the success of the egress door unit is the frame the door is hung in. The strength and durability of the frame will affect the success and longevity of the commercial door unit. The type of frame to go with the door can be changed depending on both the style or look you want to achieve, combined with the type of wall and sealing options you require.

A ‘box’ style frame is chunky, square, and sits within the wall with no overlap. This has a modern square look with minimal lines or angles. The seal is completed with either flashings or wall and window sealant.

A frame with a flange tends to have more lines and angles. The flange overlaps onto the surrounding wall and acts as a barrier over the small space between the wall and the frame. Flashings may still be needed. Sealant will also be needed, but it does not play such a large part in closing and sealing this space off.

If the construction company building the commercial building does not have a preferred choice, the type of frame is often chosen by the Project Manager on site. They select based on looks and how they prefer to fit the egress door unit in the type of wall they are dealing with. Although this fitting needs to abide by building standards on closing in a structure, and sealing it off, there is more than one way to complete this according to the building code.

The sill is another important part of the completed unit. Normally industrial buildings have a concrete floor, which is recessed at the doorway to stop water flowing under the door. Sills (the bottom part of the frame running underneath the door) normally help to seal this space. However, sills are normally left off the unit as the doorway is subject to heavy and often rough traffic that would chew through an aluminium sill. To compensate, an egress door is normally fitted with a seal that fills this space and expands, contracts or flexes depending on the size or height of the space under the door.

Finally, a range of features are often needed on the egress door itself. These include vision panels to allow light through or improve the vision of the through farers.

Door-closers hold the door steady in the wind and gently draw it close without any assistance from those using the door. Kick plates are normally stainless-steel plates applied to the outside of the door and are designed to help the door bear the full brunt of the wear and tear where it is worst – at the bottom of the door. This is often where users boots accidentally kick the door, use their boots to hold the door open or where trolleys or machinery hit, scrape or push against the door. The kick-plate is designed to protect the door from most of these hits to extend the lifetime of the door.

The finish of the door often forms another feature users require. Some doors need to be suitable for frequent washing down and others need a finish that will not break down in extreme weather.

Powder coating on aluminium results in a durable smooth, that is easily washed down. The standard coatings will handle a wash down of a building without wearing out or fading. They also come with excellent warranties from their manufacturers. The aluminium behind the powder coating will not rust if it is exposed to the weather.

Fibreglass skins are also weather resistant and suitable for washing down. These take a standard paint finish, and the longevity of this finish is dependent on the paint and application used. Once again, if the fibreglass is exposed to the weather, this will not affect its performance.

Tempered hardboard or solid timber is an older way of constructing a commercial door. In exterior situations this is not suitable as timber will break down when it is fully exposed to the weather. This is regardless of whether it is well sealed with paint or sealer. The sun and UV will crack and split the surface which allows moisture to penetrate. Solid timber is suitable in situations where the entry is well sheltered with a roof to protect it from the weather, but most industrial situations do not allow for this.

What are the possible pitfalls to watch out for when selecting the manufacturer of an egress door for your project?

- Failure of the inner construction of the door

- Surface denting

- Easy break-ins

- Doors drooping within the frames

- Premature wear and tear

- Water egress

Read a full summary on the issues that can come up with this type of door and how to ensure you can avoid them in this article here.

View the Parkwood Commercial Egress Personnel Access Door Range