POSSIBLE PITFALLS WITH PERSONNEL ACCESS EGRESS DOORS

Personnel access doors are subjected to harsh treatment, both from their everyday users, and the weather. They need to stand up to such use and hold out for the lifetime of the building.

When selecting your type, material, or brand of egress door, you need to be aware of the things that could go wrong in its performance and longevity. Certain materials and construction methods are used in the building industry today, that are not suitable for their application and industrial use.

Learn about what issues your building may face in the future, so you can make the best choice on the type, brand, and features of the complete egress frame unit. Personnel access doors are used in industrial areas, fire exits, high security areas, engine rooms, thermal environments, and commercial buildings.

Free Revit and DWG file download for PA doors

Inner Construction

Firstly, be aware of the inner construction of the door. Some commercial personnel doors have a nice outer finish, but their inner structure can be weak and unreliable.

The structure of the stile is important as it holds the locking system and is where the hinges are fixed to the door. Some manufacturers produce a door that has an outer shell and is filled with an expanding foam. The only fixing place for the lock and the hinges is this outer shell. As such, there is no full box section stile. What can happen in this case is the small fixing points, such as the ones that hold the lock in place, can come loose and the lock begins to rattle and even come out, causing major security issues. Meanwhile, the whole door lacks strength and stability due to the absence of structure inside the door. It can bend and expand when put under force.

Solid timber stiles or rails in the door can give the door a solid feel and gives the locks and hinges something to fix into. However, a natural product put into a commercial situation, and exposed to harsh elements will not survive the test of time. The timber will bow and twist the door as it will either get moisture into it as the water works itself behind the skin of the door, or the timber will heat up inside the metal capping and skin which will also cause it to bow and twist.

We recommend you find an egress door that has a full box section in the stile, that can be used to fix the locks and hinges, made from metal or composite materials over against natural materials, for maximum stability.

Surface Denting

These foam filled doors also have no backing to their flat surfaces meaning they can easily be dented or pushed in. A flat smooth powder coated surface shows up any type of dent, both small and large. It is important you select an egress door that has sufficient structure to support the flat skin. This normally means a backing support. Aluminium or steel skins are normally maximum of 2mm thick, so they cannot withstand the bumps and scraps that are an everyday occurrence in an industrial situation.

Some doors use plywood or other flat timber underneath the skin for support. However, if moisture gets into this timber, it can swell and bow the door or at least the surface of the door. Furthermore, timber will break down in the severe heat that comes about when the skins are powder coated dark colours. According to Parkwood’s testing, door surfaces have been known to get up to 70 degrees Celsius, and more. The surface fixed or glued to the timber support will cause the timber to break down over time under such heat.

Easy Break-ins

When selecting your personnel access egress door, think hard about how you can improve its security.

A common method of breaking down a door is by simply ramming it with either the corner of a vehicle or a battering ram. What holds the door closed is the lock and the bracing around the lock, so this area of the door is critical in withstanding forced entry.

A lack of support and structure around the lock will cause the door to cave in, leaving the lock in place. Timber doors will split and break apart in this area, as it gets machined fairly thinly on both sides of the mortice. A metal or aluminium box section stile around the lock, that also runs to the top or bottom of the door, will hold the door together in the event of this type of break-in. Metal or composite only needs to be a few millimetres thick to have reasonable strength.

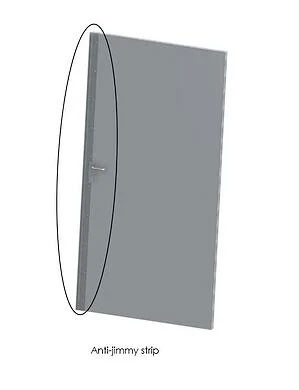

Another method of breaking through a door is to lever the door open by forcing in a crowbar and leveraging the door open. As the door is normally hung so it is open out, there is no frame jamb surrounding the door on the outside, so it is easy to insert a crowbar. To avoid this, you should select a manufacturer that can fit anti-crowbar or anti-jimmy bar attachments to the door. This is a metal fin which attaches to the door and overlaps onto the frame. This covers the space between the door and the frame and stops anything getting forced in-between the two. Some manufacturers are now offering anti-jimmy capping which looks more appealing.

Door Dropping

The door can drop within the frame for two reasons: the door structure itself droops and falls out of square, or the hinges bend and twist allowing letting the door droop off the jamb. If a door drops within the frame, it will scrape on the floor damaging the door, floor, and the seal on the bottom of the door. It will become very hard to open and close, and could even jam shut.

Find a door manufacturer that has reasonable bracing within the door. This could either come from the stiles and rails within the door forming a long-lasting brace, or a stable inner core that is formed in such a way it cannot change shape or drop over time. Normally you cannot tell how a door is made once it is on site, but good manufacturers will include cross sections and descriptions in their marketing.

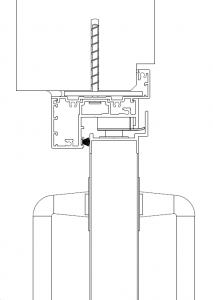

Strong commercial hinges are also important. Some manufacturers have a recess on the edge of their door that the hinge will fit snugly into. There is a similar shape on the frame. This stops the hinge twisting on the door and frame. It also helps to support the hinge and keep it in the right place. This decreases the likelihood of the hinges getting bent and the door drooping.

Premature Wear and Tear

As personnel egress doors are subject to high levels of wear and tear, they can break down much faster than your standard entry door. Personnel doors are used for a lot of heavy traffic, such as small machines, trolleys and a lot of work boots, especially when the main roller doors are left closed. They are also normally placed in highly exposed places as most factory buildings do not have shelter over their smaller exits and fire exits. Over time, this wear and tear and break down a reasonably solid door.

To extend its life, we recommend choosing an egress door that is powder coated aluminium or composite skin, over against a timber or hardboard painted surface. These surfaces will resist harsh weather combined with knocks and bumps.

Secondly, additions to the door such as kick plates and help to protect the areas of the door that are most vulnerable. These plates normally come in stainless steel and match the other hardware on the door or surrounding area. They are fixed on the outside after the door is manufactured. The most common option is a 200mm high plate, across the full width of the door, placed at the bottom where it gets the most hits from boots and wheels of trolleys and machines.

Water Egress

Water can find its way into extremely small places, especially with the help of wind. Poorly designed doors and frames can allow water to be blown through tiny spaces, even without the help of gravity causing the water to run.

Select a door with seals on all the jambs to ensure the door is not only closing against a solid jamb, but also against a compressible weather seal.

The space along the bottom of the door may not have a sill. In industrial and commercial situations, the sills quickly get worn down, even if they are made from suitable material, so the door and frame unit does not normally have a sill. To prevent water egress under the door, select a personnel door manufacturer that offers a seal under the door. This could be in the form of a rubber wiper seal that automatically fills up the space between the door and the frame. Alternatively, there are a range of seals on the market that sit inside the bottom of the door and are activated and drop down once the door is closed into the frame.

Don’t Put Your Industrial or Commercial Building at Risk, find a manufacturer of personnel access egress doors that understands these problems and has designed a product that overcomes and eliminates such issues.

View the Parkwood Commercial Egress Personnel Access Door Range